So how do we get from “wouldn’t it be cool” to the actual locomotive? An engineering team, led by Jason Lamontagne, joined by Rick Sisson, Harold Downey, Eric Shade, Gordon Cook and Alan Downey, is using modern methods to take the locomotive piece- by-piece from a series of sketches to computer-assisted designs and finally to the shop to become a real piece of iron or steel.

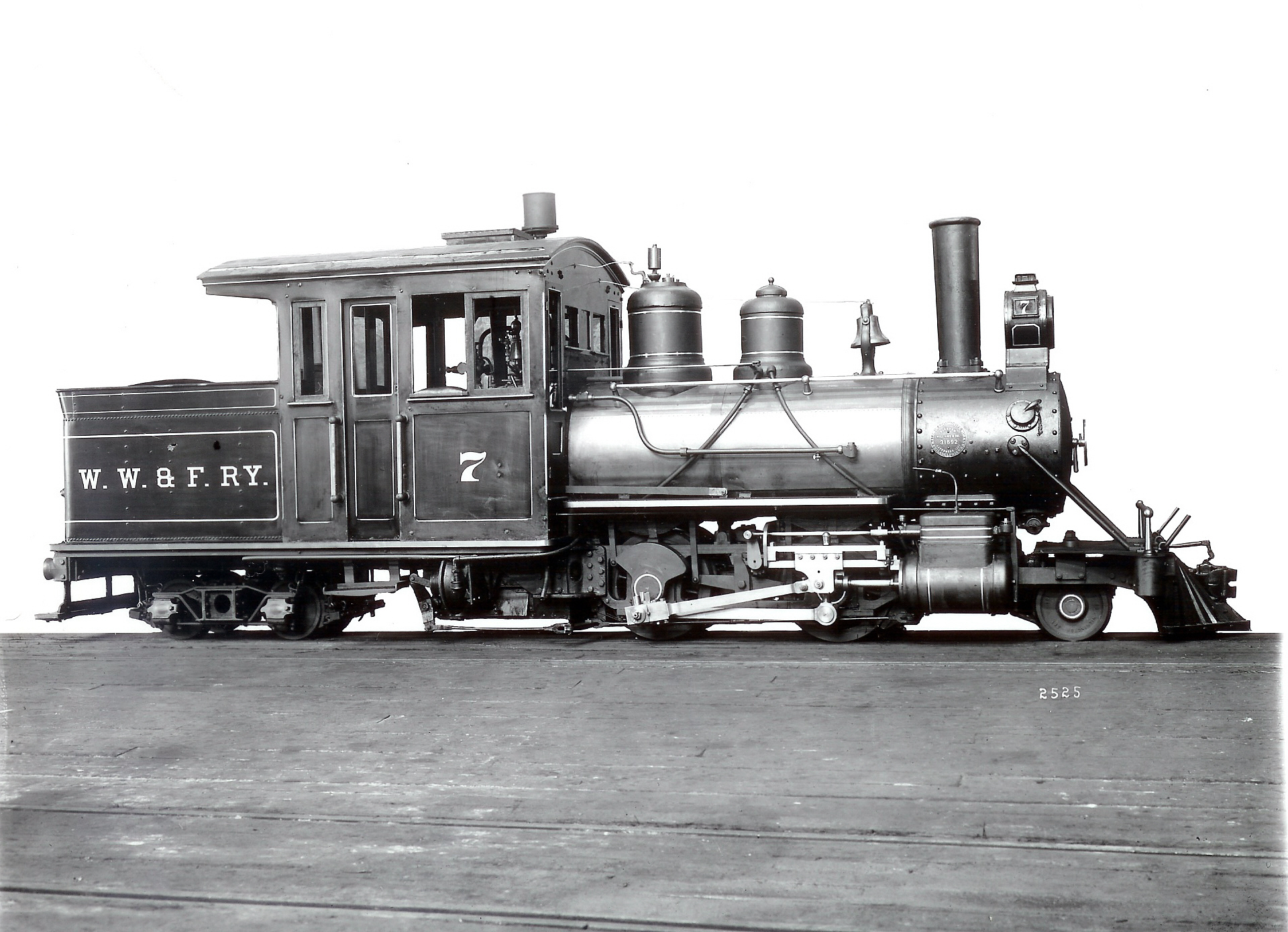

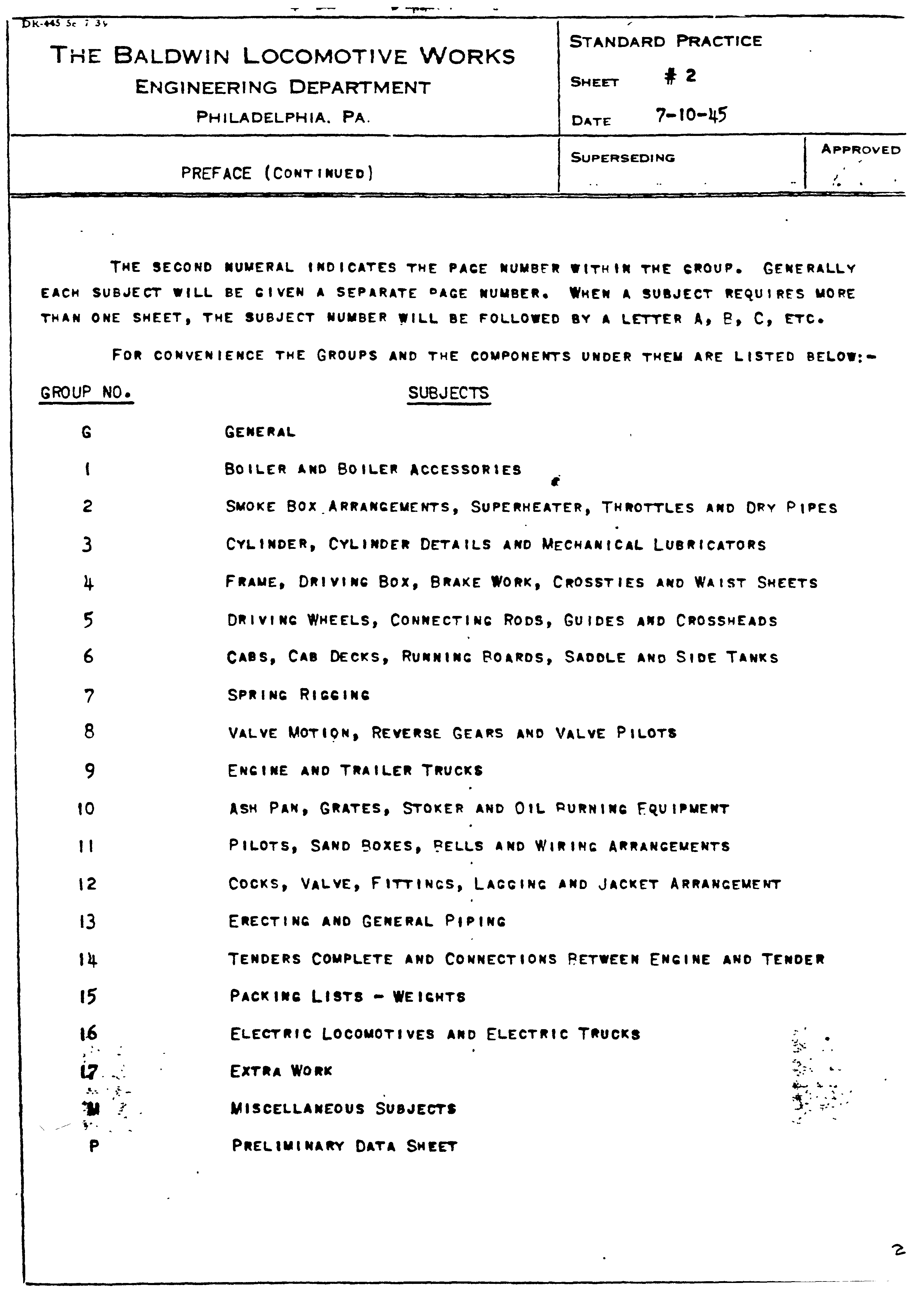

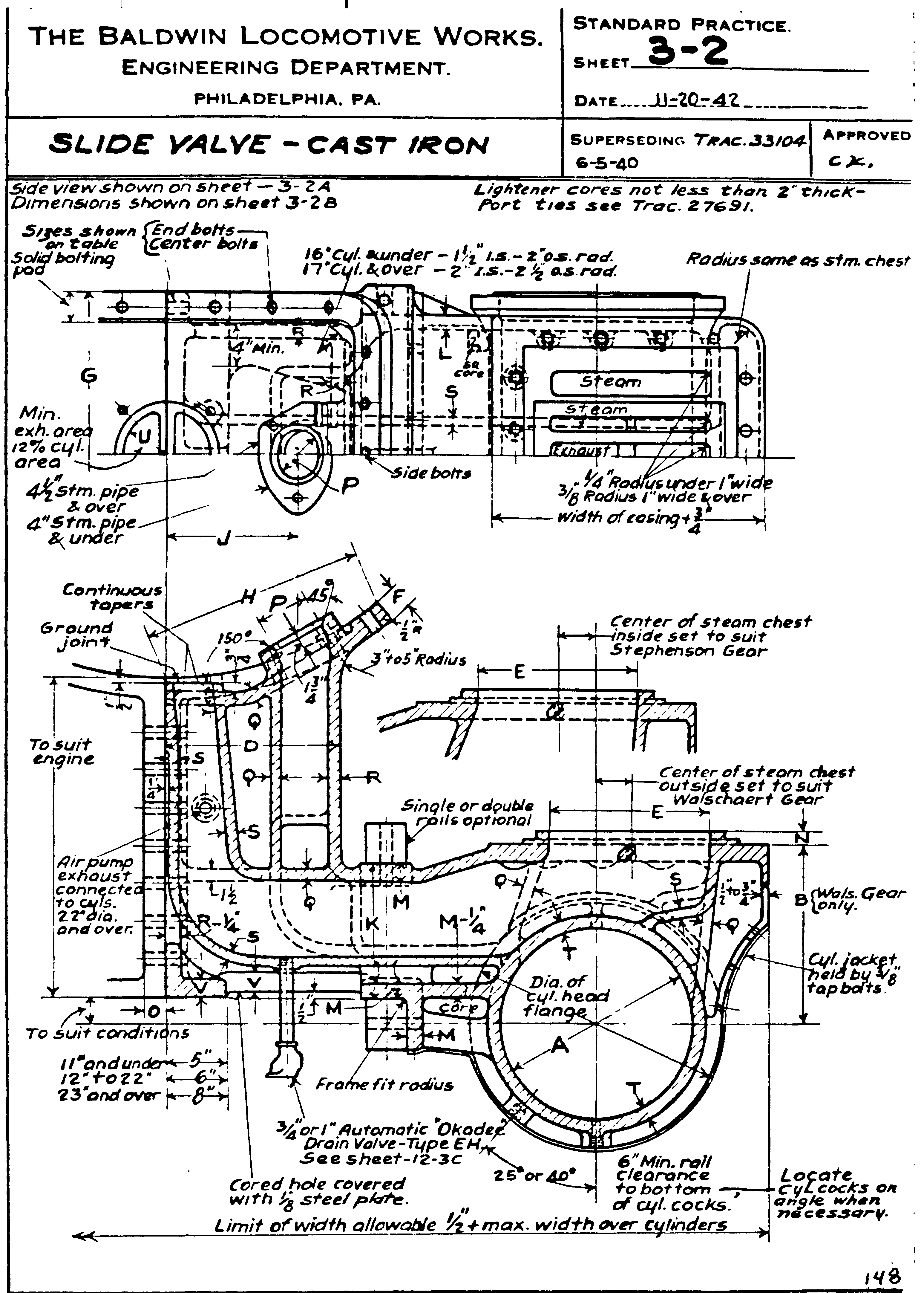

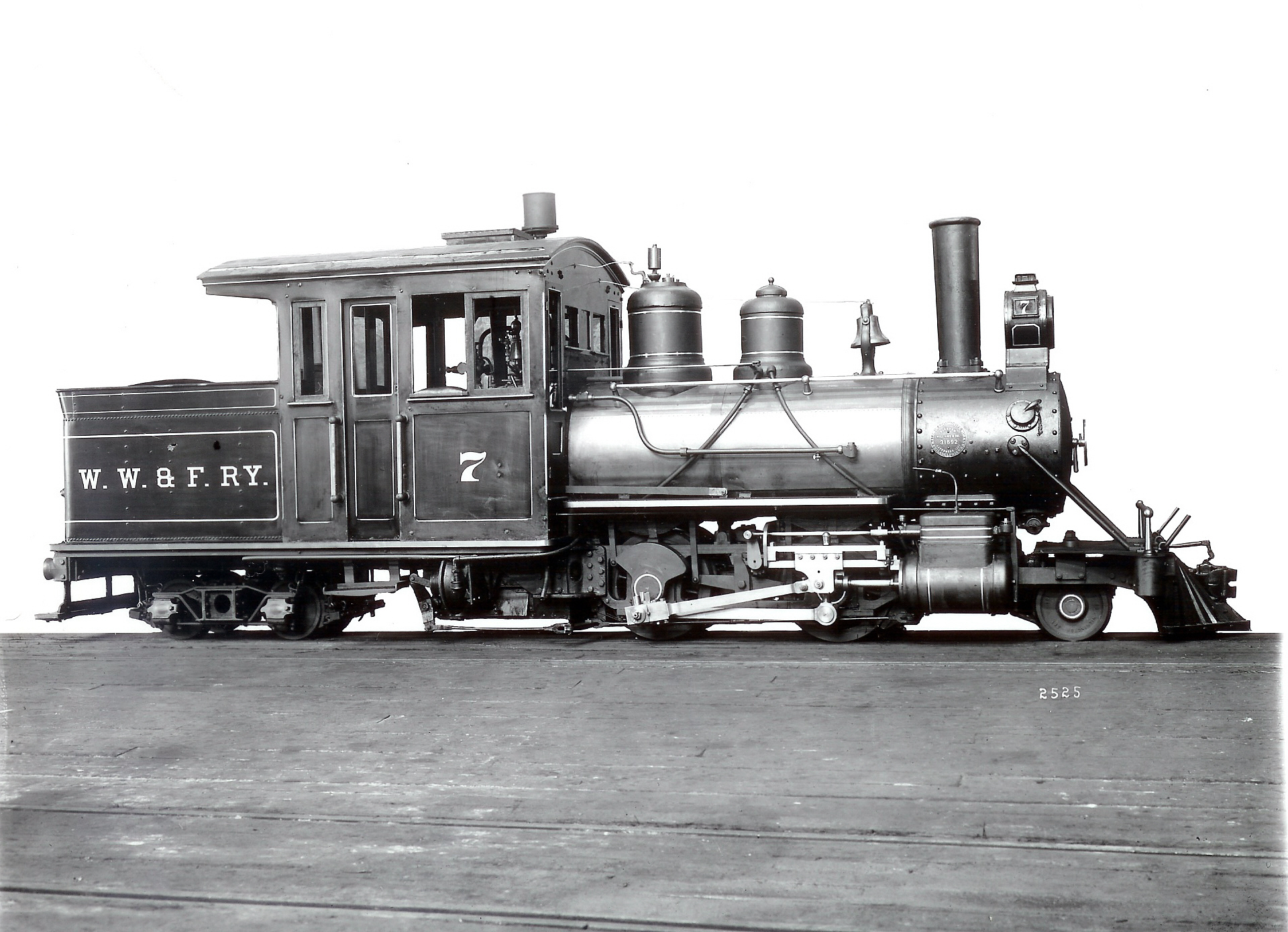

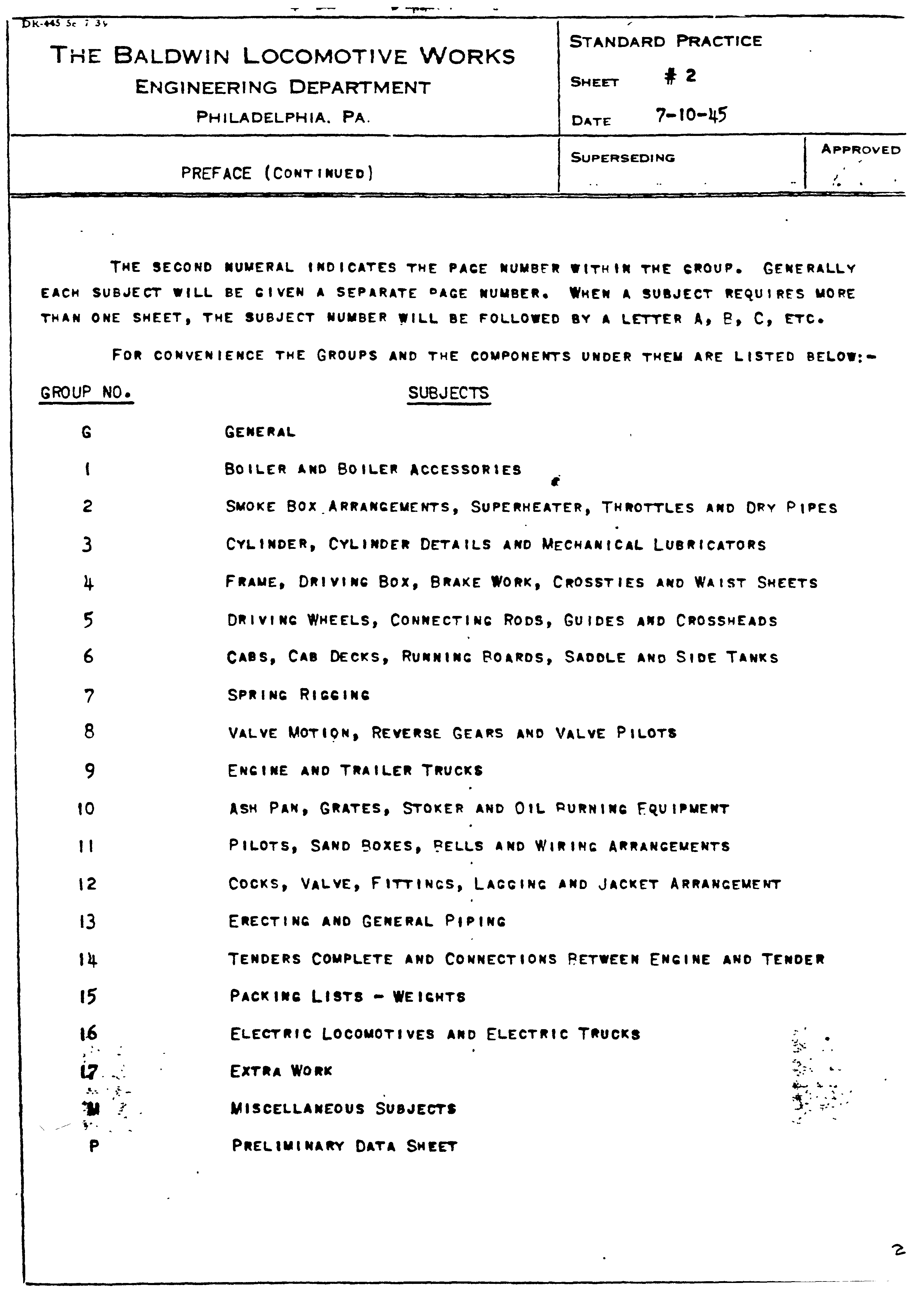

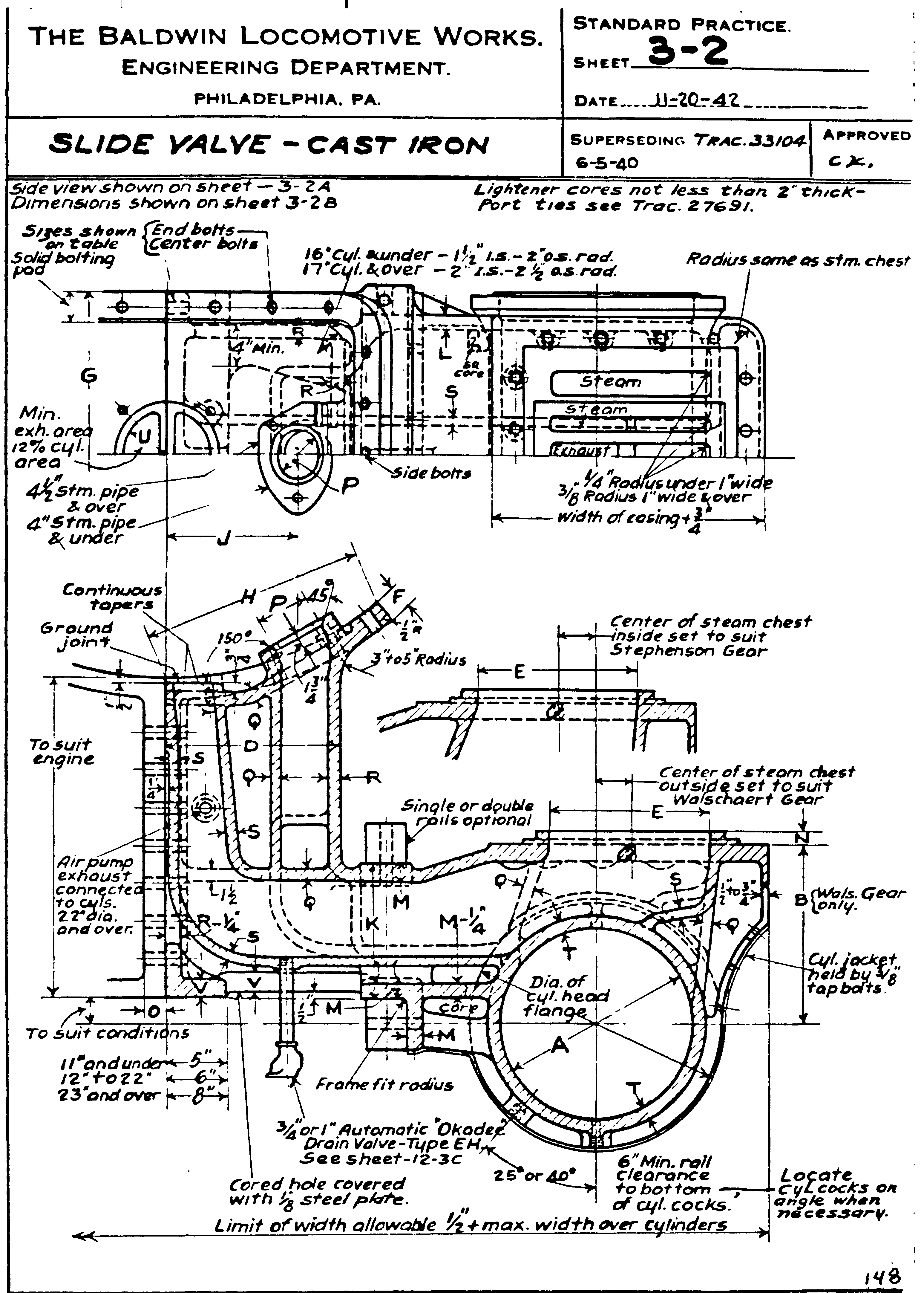

WW&F No. 7 was scrapped in 1937. Fortunately for the team, Baldwin Locomotive Works had developed a very methodical and logical approach to locomotive construction. Virtually every piece and part that went into a Baldwin locomotive was of a standardized design. Baldwin engineers relied on the company’s Manual of Standard Practices, which defined the dimensions and materials for every component, for guidance. By following those specifications, these components could be made, no matter the gauge or size of the locomotive.

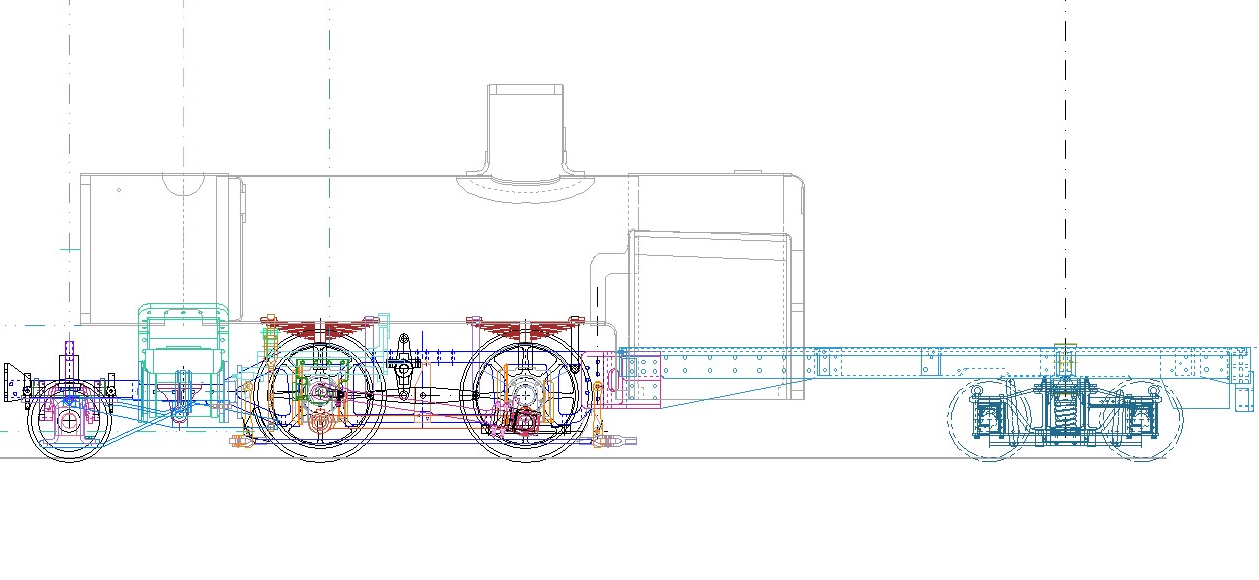

Our WW&F team is following those same standards as they design and draw the many components, which, once assembled, will become WW&F No. 11. The team meets weekly on Zoom to discuss progress and challenges. Each member of the team has been assigned a series of related components, which will become sub-assemblies of the locomotive. Rick Sisson manages a spreadsheet to track completion of drawings and patterns, while Eric Shade carefully checks each drawing against the standards.

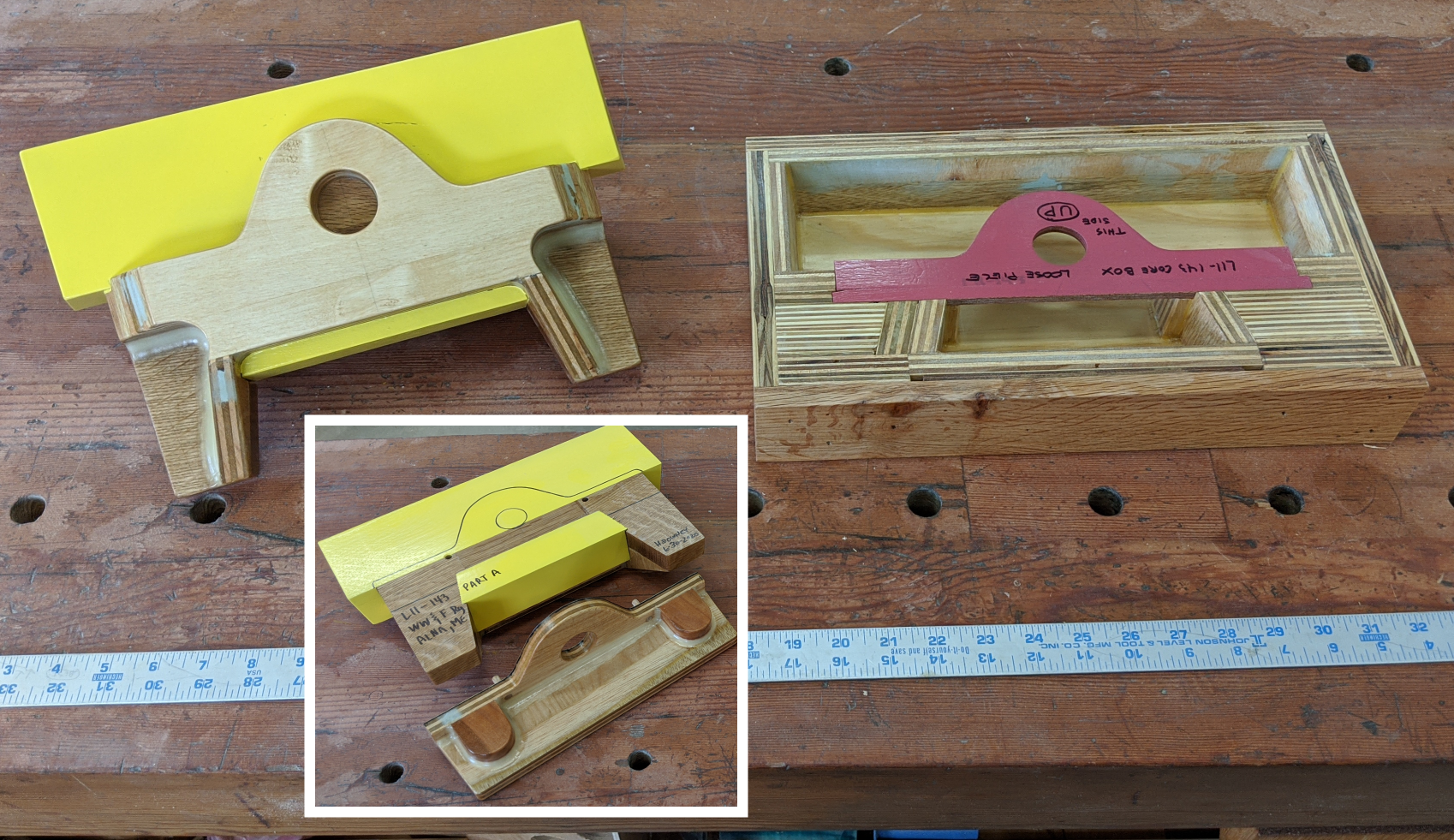

The process begins with an old-fashioned sketch on paper, with the necessary dimensions indicated, sometimes with an arrow pointing to a particular place or a circle indicating an area for special attention. Following the sketch, several two-dimensional computer drawing are made, including all dimensions for rivet or bolt holes, angles, fillets or any other modifications.

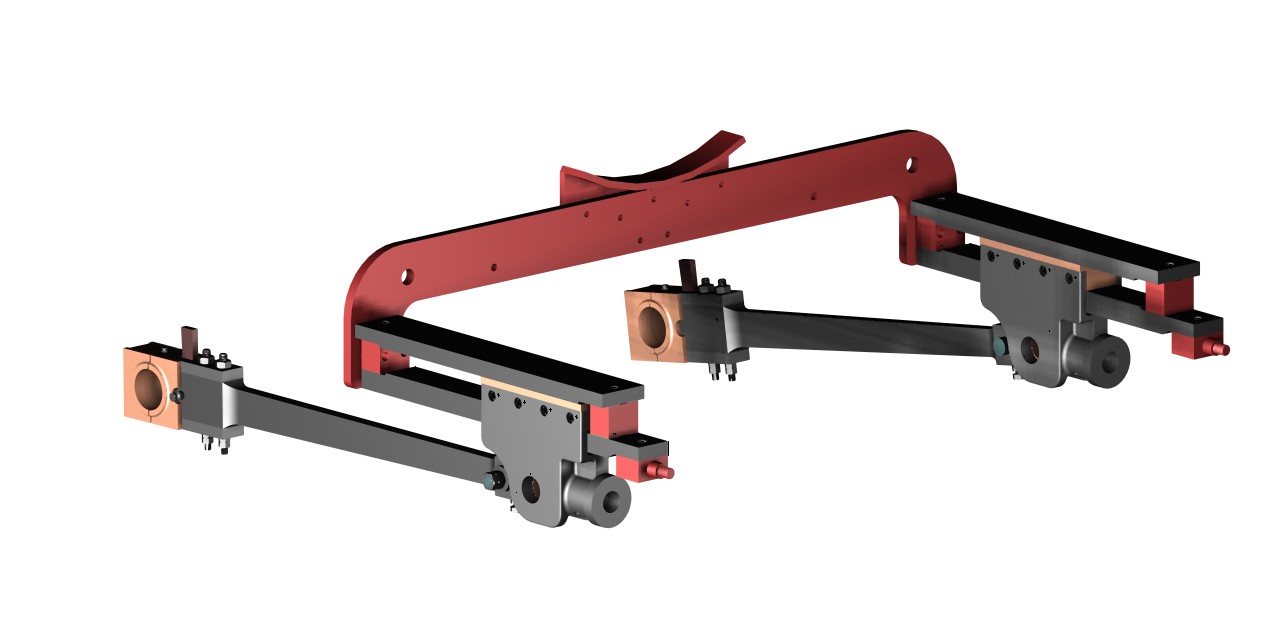

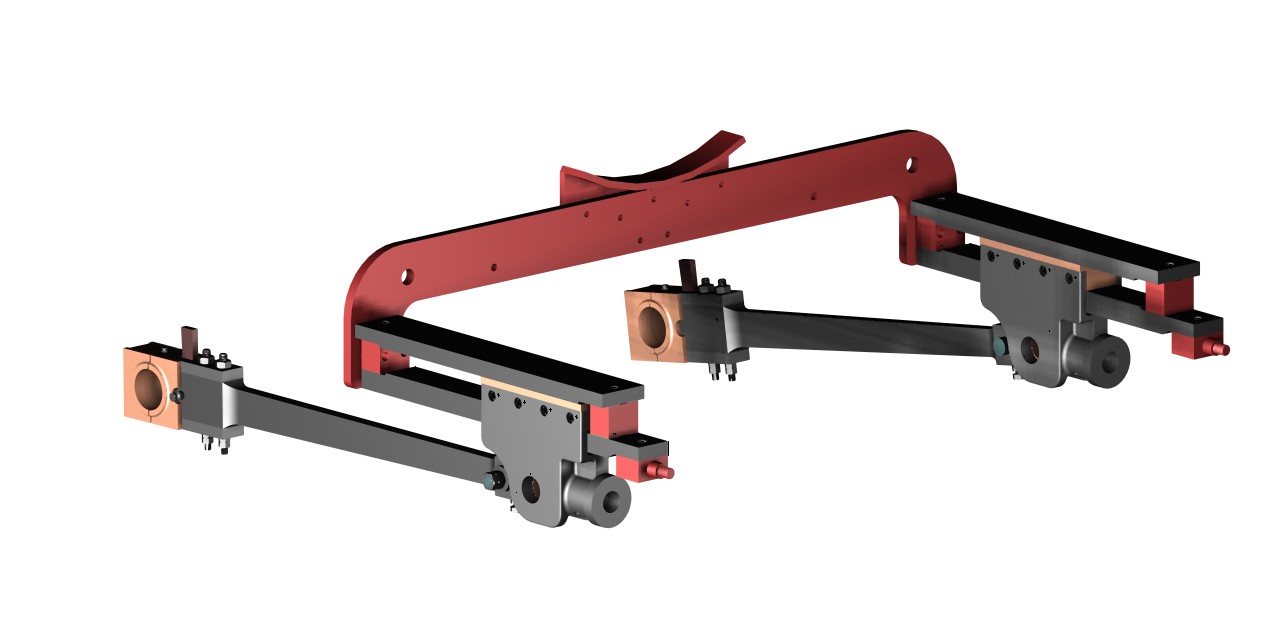

The exciting part comes next, as the two-dimensional drawings are converted to a 3-D images using one of several Computer Assisted Design programs. A 3-D image offers the design team the opportunity to “see” what the finished object will look like. The image can be manipulated on the screen to allow viewing from any angle, it can be enlarged to show detail, and in very complex designs, such as the cylinders, it’s even possible to see interior details. Various smaller parts can be “stacked” on the screen to show the final product. In fact, a 3-D image can be “printed” to make a foundry pattern.

The first parts manufactured in 2020 for No. 11 should be at Sheepscot soon. These are the two main frame rails and two pallets of smaller parts. All were made using CAD prints produced by the engineering team and sent to Precision Grinding, Inc. of Bessemer, Alabama. Parts were produced by computer-controlled plasma-cutting, a polishing process known as Blanchard grinding and final machining.

The fund-raising for No. 11 continues apace. The first on-line campaign on FundRazr kicked off on June 11 and raised its first $1,000 in less than two days. In addition to the on-line contributions, funds were mailed directly to the WW&F post office box. Our goal by the end of 2020 is $17,000, which will set up the budget for the first year of the project of $50,000. Have you donated yet?

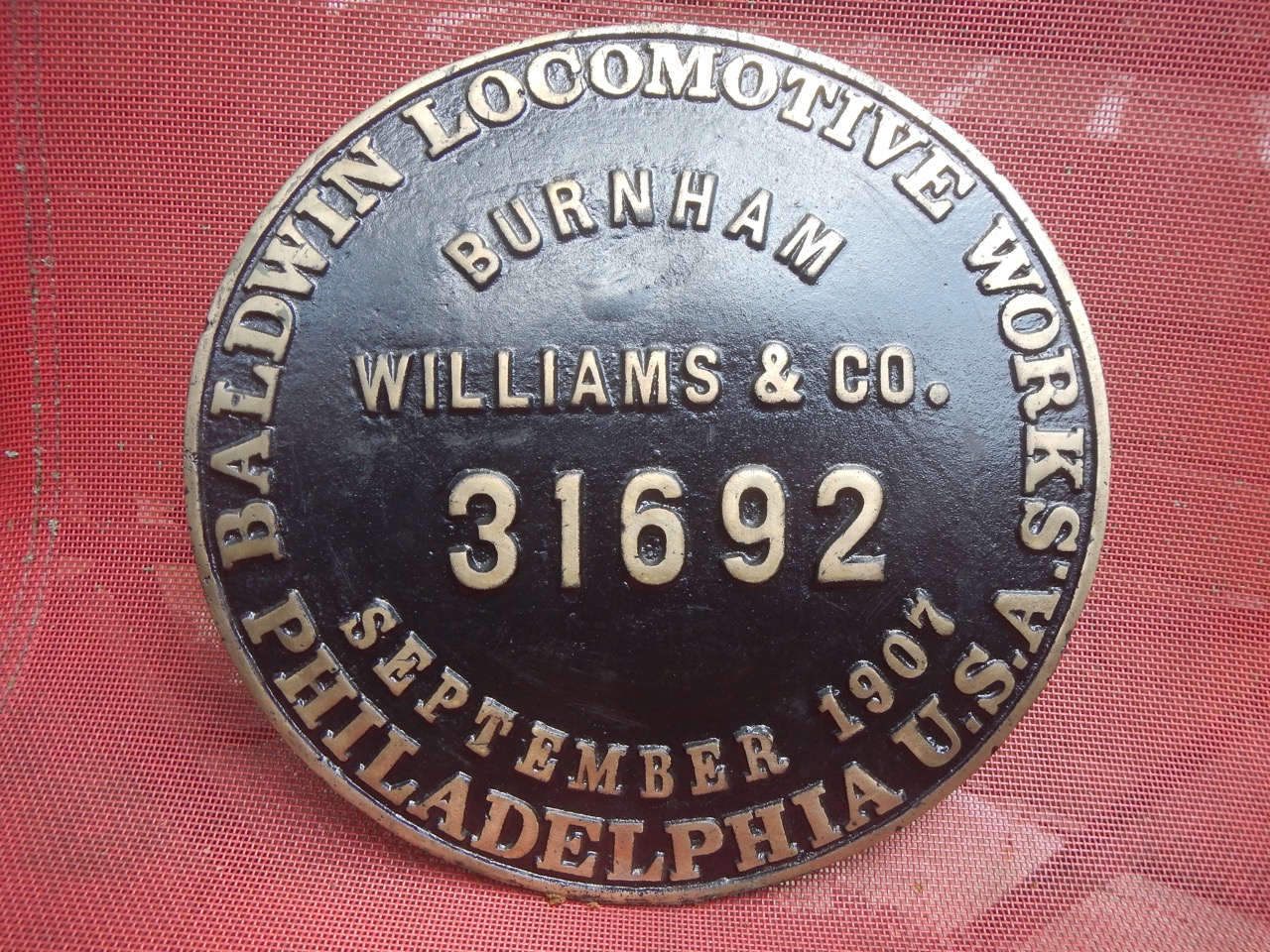

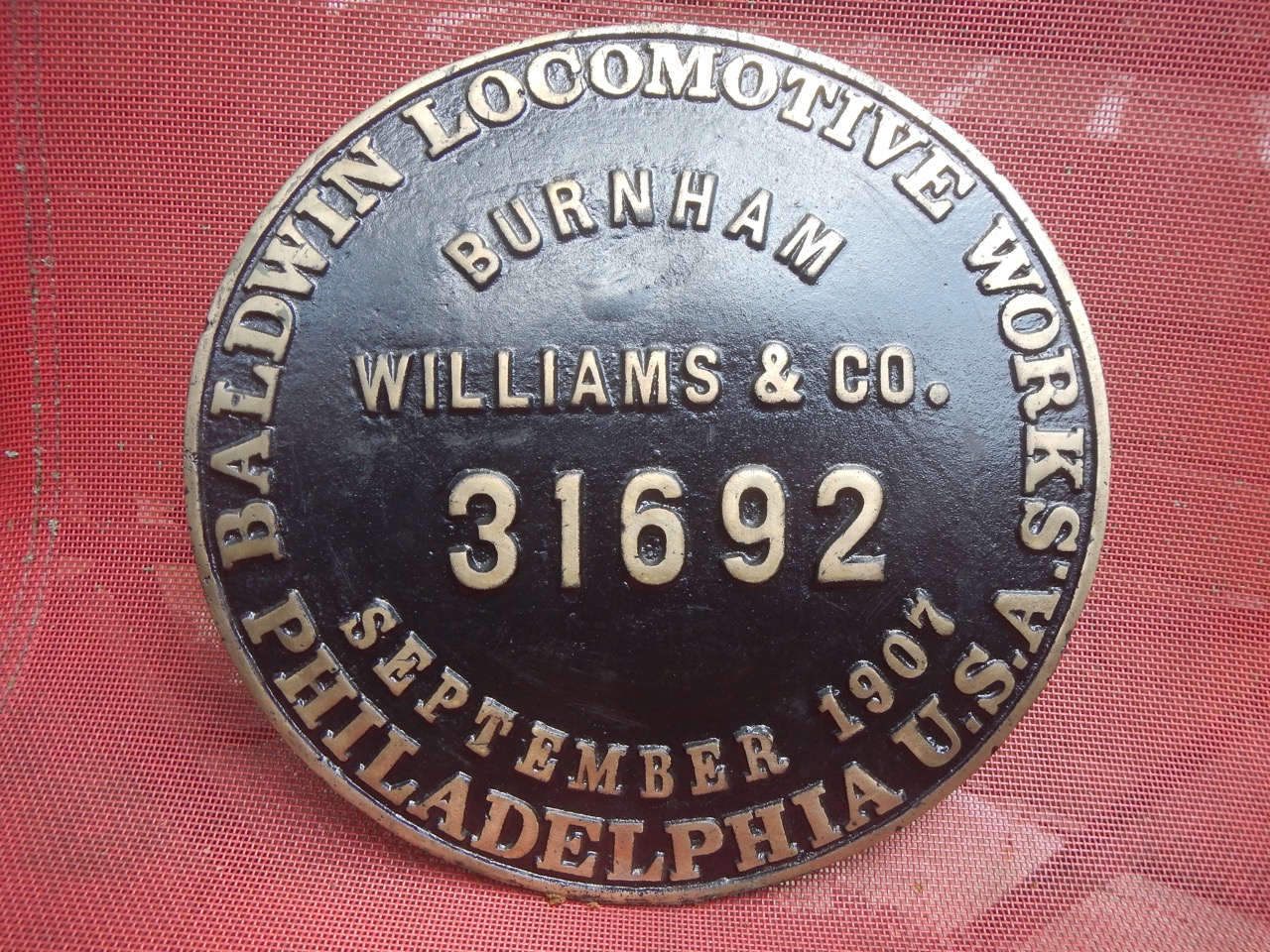

Don’t forget the special gift for anyone who donates $1100 or more in a single check. We will give each of those generous individuals a full size bronze replica of WW&F No. 7’s Baldwin builder’s plate, produced at Cattail Foundry in Gordonville, Pa.

Learn more and donate at: build11.wwfry.org