A special Build 11 update from one of our volunteers…

Gordon Cook has been spending several days each month at the museum, most recently running the horizontal mill. He’s been finishing work on two rear frame bolster castings. These and three additional castings form the support for the rear truck under the tank and are an important component of the rear frame of No. 11.

These pieces need to be faced on five sides so the entire assembly is square and tight with the strength to support the weight of the water tank and coal. In addition, they must resist twisting and bending forces as the locomotive rolls around curves and on uneven track

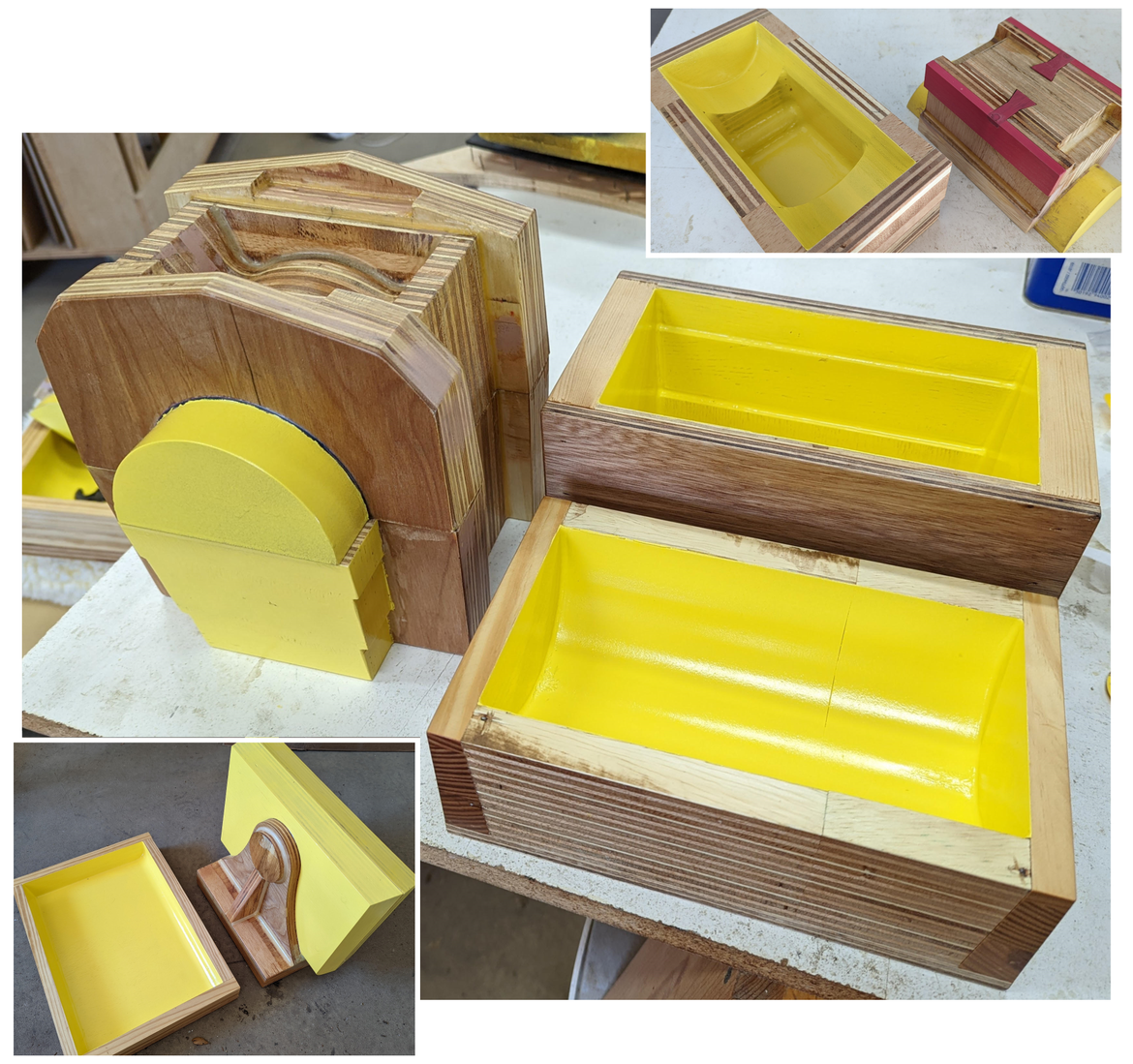

Harold Downey has been at work in Texas, making patterns for a number of components for No. 11. Photos show the front spring equalizer pedestal and core box, the lead truck oil cellar and core box and the lead truck journal box and core boxes. This is all rather tedious work, and Harold has continued to do this, along with a number of engineering drawings for No. 11. He’s also working on patterns for several small parts for coach No. 9.

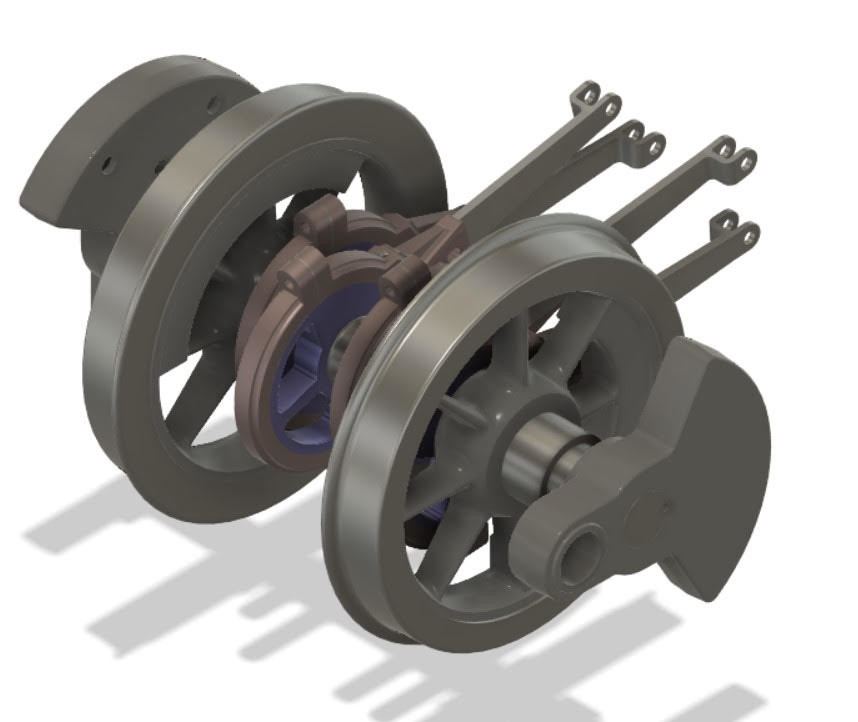

Gordon and his friend Dave Roche made a “solid model” of the main drivers, with the cranks and the valve gear, to prove the angles needed for the key ways in the axles. Gordon explained that this was necessary to make certain everything was correct prior to manufacturing the axles, especially the cutting of the key ways.

Friends, we’re well into the 2022 fund raising effort for No. 11, and we’re grateful for all the donations to the project. About 35 individuals, some being one-time donors, while others are regular monthly or bi-monthly donors, have contributed about $3,700. However, we need to receive at least $982 every week for the remainder of the year if we intend to reach our $70,000 goal for 2022. Don’t forget, we have a standing offer of $25,000 in matching funds that is only activated when we achieve $25,000 in individual donations. If you are able to do so, please help us Build 11.

Can you help make this dream a reality?

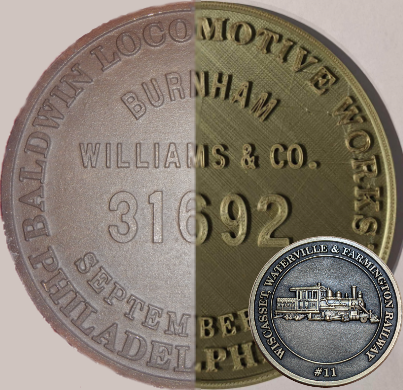

Remember, we have two great premiums for donors. For $1,100 or more, you can get your own full-size bronze replica of WW&F No. 7’s Baldwin builder’s plate. For just $110, you can receive a high-quality 3-D plastic casting of No. 7’s plate, and in the WW&F’s gift shop, we’ve got the No. 11 Challenge coin for only $11.

Contribute at www.build11.org

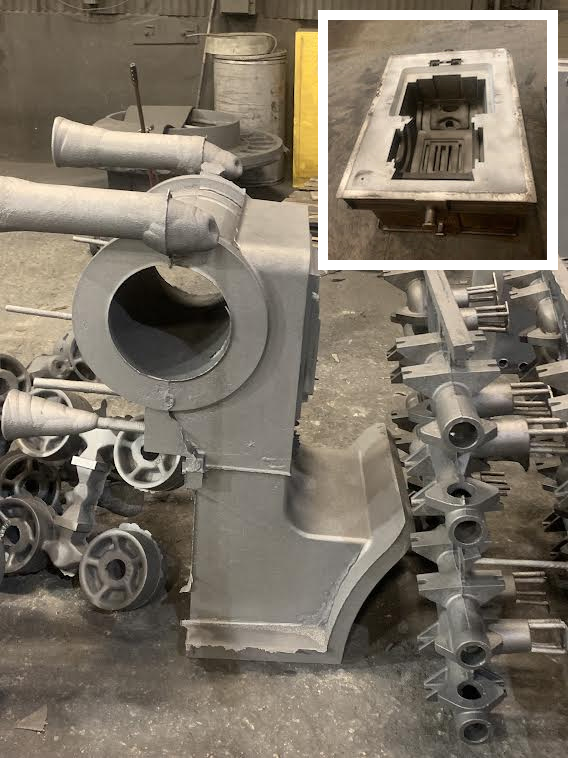

And the best news of all, on January 5, the folks at Dakota Foundry poured the first cylinder half-saddle for No. 11. The 1800-pound casting is a major component of the locomotive, and the other half, as well as other major parts of the locomotive chassis, will be poured in subsequent days. Dakota Foundry has been major partner in our effort, overseeing and producing these complex castings, a point of pride for them.

And the best news of all, on January 5, the folks at Dakota Foundry poured the first cylinder half-saddle for No. 11. The 1800-pound casting is a major component of the locomotive, and the other half, as well as other major parts of the locomotive chassis, will be poured in subsequent days. Dakota Foundry has been major partner in our effort, overseeing and producing these complex castings, a point of pride for them. On February 2 and 3, the build 11 team is planning the first of what we intend to be regular work days devoted to making and finishing parts for No. 11. We are looking for some more folks who would like to be involved in this project, and we invite anyone interested to sign up to join us.

On February 2 and 3, the build 11 team is planning the first of what we intend to be regular work days devoted to making and finishing parts for No. 11. We are looking for some more folks who would like to be involved in this project, and we invite anyone interested to sign up to join us.

Learn more and sign up at: www.wwfry.org/volunteer

Learn more and contribute at build11.org

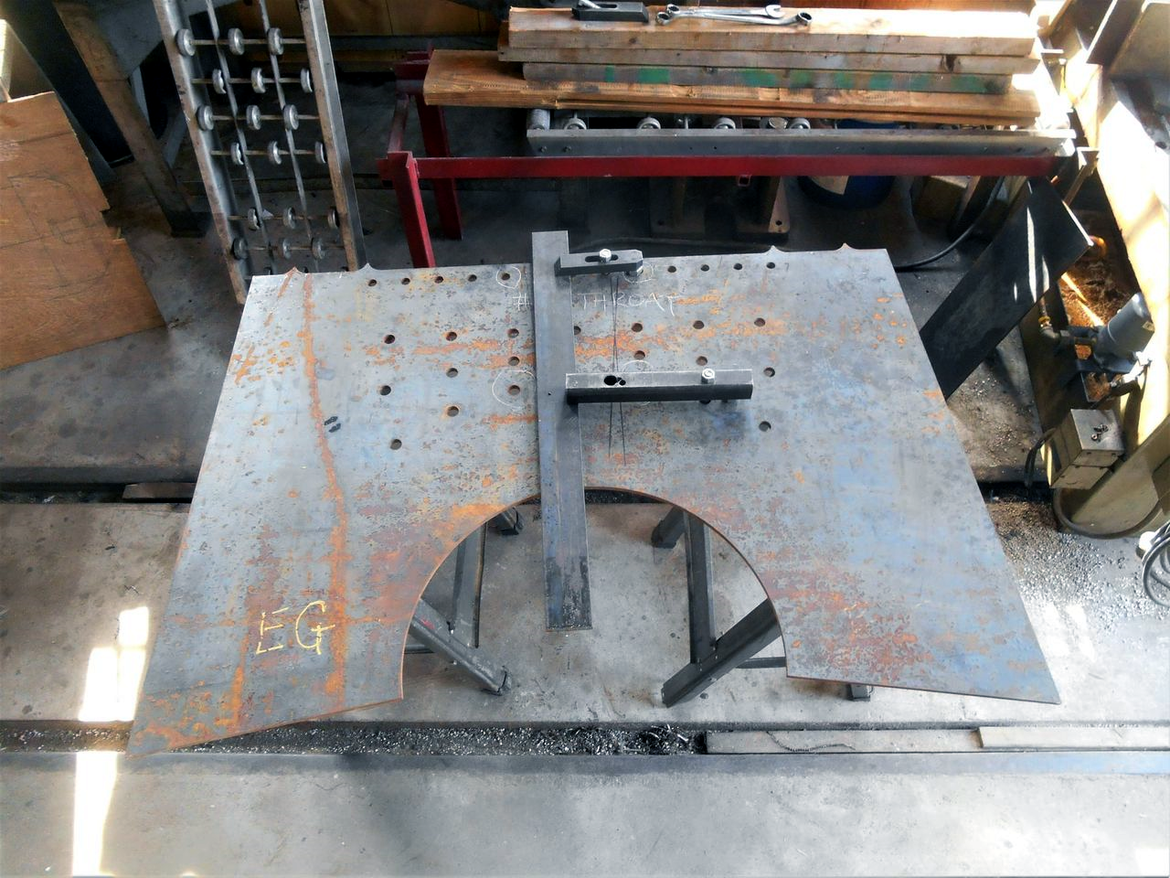

On Nov. 30 and December 1, a four-man crew including Jason Lamontagne, Gordon Cook, Rick Sisson and new volunteer Eric Snyder completed flanging the throat sheet for No. 10. This work included forming the knuckle by hand, using wooden mallets to form the final curve over a die. The flanging machine was used to hold the workpiece in position on the template during this operation.

That work completed the flanging of components for No. 10’s new boiler. They will be sent out for normalization by heat treatment, and when the parts are returned, the crew will begin to fit-up and test assemble the parts before sending them to Maine Locomotive & Machine for welding. This should mean that No. 10’s boiler will be completed other than installation of the flues. Sometime in late winter or early spring the boiler will be reunited with No. 10’s frame, and we may then see No 10 returned to service sometime in 2022!

After the parts for No. 10’s boiler are sent to ML&M, the next step will be to make the throat sheet for No. 11’s boiler. That’s the last component for the boiler, so all those parts can also be normalized.

The latest word from Dakota Foundry is that a subcontractor making the cores for No. 11’s cylinder half-saddle castings is backed up, and they now expect to cast them in January. They will cast our other components — drive wheel centers, cranks and rear frame extension at the same time. They will go to another shop for heat treatment to produce ductile iron.

We can sympathize with Dakota, as our shop is backed up with projects, too, and there is currently no space available for us to begin assembling No. 11’s frame at this time. Next spring….

We can sympathize with Dakota, as our shop is backed up with projects, too, and there is currently no space available for us to begin assembling No. 11’s frame at this time. Next spring….

As we raise funds to build WW&F No. 11, we previously had two levels of fund-raising, the full-size brass builder’s plate for $1100, and the 3D printed mini builder’s plate for $110. Now we’ve got something for everyone! For just $11, you can have the Build 11 Challenge Coin. Challenge coins started in the military, with each outfit making their own coins. The lore around these coins is that if you challenge someone with your coin, and they have theirs on hand, you have to pay the penalty — buy a round of drinks or do push-ups. Otherwise, they pay.

Due to a mix-up in the manufacturing process, the first 100 coins have a spelling error, never to be reproduced. These coins will make great stocking-stuffers! If you want one, you can buy one from the WW&F Museum Gift Shop for $11. Once they’re gone, they’re gone, and the new ones will be correct.

In other news, the 2021 fund-raising effort for the Build 11 Project is winding down. It will conclude on Dec. 31. Right now, the total on hand is $89,118, which is 178% of our $50,000 goal. To all of you who have supported this project in 2021, thank you, thank you. We’ll be announcing the 2022 version of the Build 11 Project on January 11, 2022.

Finally, may we wish everyone who follows this project a Merry Christmas and a happy, healthy and prosperous 2022!

Dakota Foundry reports they have completed all the patterns and cores for the cylinder half-saddle castings for No. 11, and they sent some photos. They will be preparing the molds and are planning to pour the pieces soon. We can expect the completed castings, each of which will weigh about 1500 pounds, sometime around the end of the year.

This photo shows the completed pattern for one half of the mold. As you can see, it is a large piece. The tape measure at the bottom shows that it is about 32 inches wide.

This photo shows the completed pattern for one half of the mold. As you can see, it is a large piece. The tape measure at the bottom shows that it is about 32 inches wide.

This photo shows several of the cores and core boxes, which create cavities inside the mold during the pour.

This photo shows several of the cores and core boxes, which create cavities inside the mold during the pour.

This image is of the cope, or top half, of the two part pattern used to make the casting. On the right side, the curve is where the casting will be mated to the smokebox of No. 11. At the center left is the valve portion of the casting, and on the extreme left is where the frame of the locomotive will be bolted to the half-saddle. The bottom half of the mold (not shown) is known as the drag.

This image is of the cope, or top half, of the two part pattern used to make the casting. On the right side, the curve is where the casting will be mated to the smokebox of No. 11. At the center left is the valve portion of the casting, and on the extreme left is where the frame of the locomotive will be bolted to the half-saddle. The bottom half of the mold (not shown) is known as the drag.

In other news concerning Dakota Foundry, the drive wheel center patterns, as well as the cranks (created by Bernie Perch) and the rear frame extension (by Alan Downey) castings, were crated by Harold and Alan Downey and were picked up by the trucking company on Thursday morning. Those pieces will be ductile iron rather than grey iron.

In other news concerning Dakota Foundry, the drive wheel center patterns, as well as the cranks (created by Bernie Perch) and the rear frame extension (by Alan Downey) castings, were crated by Harold and Alan Downey and were picked up by the trucking company on Thursday morning. Those pieces will be ductile iron rather than grey iron.

Several members of the No. 11 Project engineering committee were in Sheepscot over the past several days, during which they continued the work of forming parts for locomotive fireboxes. Jason, Rick, Gordon (pictured) and Wayne were involved in the process, using the flanging machine to form the rear firebox and the door wrapper sheets. In addition, a method was developed to form the throat sheet using the flanger.

Several members of the No. 11 Project engineering committee were in Sheepscot over the past several days, during which they continued the work of forming parts for locomotive fireboxes. Jason, Rick, Gordon (pictured) and Wayne were involved in the process, using the flanging machine to form the rear firebox and the door wrapper sheets. In addition, a method was developed to form the throat sheet using the flanger.

Donations for No. 11 continue to come in, and donations contributed during 2021 stand now at $66,642. There is still time for you to contribute if you have not done so, however. The fund raising doesn’t officially end until Dec. 31, 2021. Donate at www.build11.org.

Finally, on Saturday evening, as No. 9 was rolling into the engine house for the first time, the two names were drawn for the raffle winners from among those who purchased raffle tickets to support our fundraising for No. 11. Grand prize winner is Bill Baskerville, and Peter Kuntz is the runner-up. Congratulations to both, and thanks to everyone who purchased tickets. The raffle raised over $1000 to help us make progress on No. 11.

Here, Wayne Laepple (center) and Jason Lamontagne (left) are positioning the first sheet for bending in the flanger.

Here, Wayne Laepple (center) and Jason Lamontagne (left) are positioning the first sheet for bending in the flanger.

Fortunately, these bends were all straight bends so no heating of the sheets was necessary. Gordon Cook (far right) and Rick Sisson (not pictured) devised a stop that allowed us to make the bends at the correct angles. For the first try, a sheet of MDF plyboard was tried. It worked fine for the initial bends, but as we progressed, the force of the flanging operation caused fasteners to elongate the holes in the pltboard. Sections of steel bar stock were successfully substituted and the work continued.

The first attempt to use steel bar as a stop, seen here, was unsuccessful. A second try, bolting the bar directly to the sheet, worked much better.

The first attempt to use steel bar as a stop, seen here, was unsuccessful. A second try, bolting the bar directly to the sheet, worked much better.

The next work session will include additional flanging of No. 11’s throat sheet, the more difficult to execute curves. This operation will require heating the sheet to make it pliable. At this time, we expect to do that in early October.

While it may seem like we did not accomplish much at this session, a good deal of time was necessary to lay out the bends to follow the contours of the sheets. The actual forming operations took less than a third of the entire time we worked.

While it may seem like we did not accomplish much at this session, a good deal of time was necessary to lay out the bends to follow the contours of the sheets. The actual forming operations took less than a third of the entire time we worked.

Here, the toggle of the flanger is just beginning to bend the steel for the initial bend.

In other news, the arrival of the “shop annex,” a 12 x 24 foot structure that has been positioned adjacent to the shop, was followed by the installation of a rack for storage of lengths of flat, angle and round steel stock, steel shelving, and bolt bins. Materials from several locations in the shop have been consolidated into this structure, which will also house various tools and equipment not frequently used that occupied valuable floor space in the shop. Thanks to Brendan Barry, the storage spaces have been set up and lighting has been installed.

In other news, the arrival of the “shop annex,” a 12 x 24 foot structure that has been positioned adjacent to the shop, was followed by the installation of a rack for storage of lengths of flat, angle and round steel stock, steel shelving, and bolt bins. Materials from several locations in the shop have been consolidated into this structure, which will also house various tools and equipment not frequently used that occupied valuable floor space in the shop. Thanks to Brendan Barry, the storage spaces have been set up and lighting has been installed.Finally, we are pleased to announce that the fund raising for No. 11 continues to move forward. As of today, the total donations raised in 2021 amount to nearly $59,500. At this time, we need just $979 to fully access the $25,000 matching challenge donation received during the spring.

Put us “over the top” for 2021 at www.build11.org

Arguably more exciting than watching the Olympics, the WW&F “FundRazr” goal of $50,000 in 2021 for building locomotive no. 11 has been achieved this week! Thank you to all who have contributed; your generosity will ensure that the project does not pause in 2022 due to a lack of financial resources.

That said, we’re not quite out of the woods yet! We still need to raise $3500 to complete the $50,000 challenge set forth by one of our most generous donors. Lean more and donate at: build11.org

Of course, any funds raised above and beyond our 2021 goal will make the 2022-2025 campaigns all the easier.

If you’ve been keeping up with the news, you know that the national economy is roaring ahead, but at the same time is plagued with a shortage of willing workers. This problem has led to a delay in the manufacture and delivery of crucial components from Dakota Foundry for No. 11. That being the case, we are temporarily shifting our focus from No. 11’s frame to No. 10’s boiler. In the coming weeks, we plan to flange the last few pieces for No. 10’s firebox, make some modifications to the front and rear tube sheets, and then take all those parts to Maine Locomotive & Machine. ML&M will move ahead with manufacturing the new boiler, welding the components as we provide them. The shell is already at their shop.

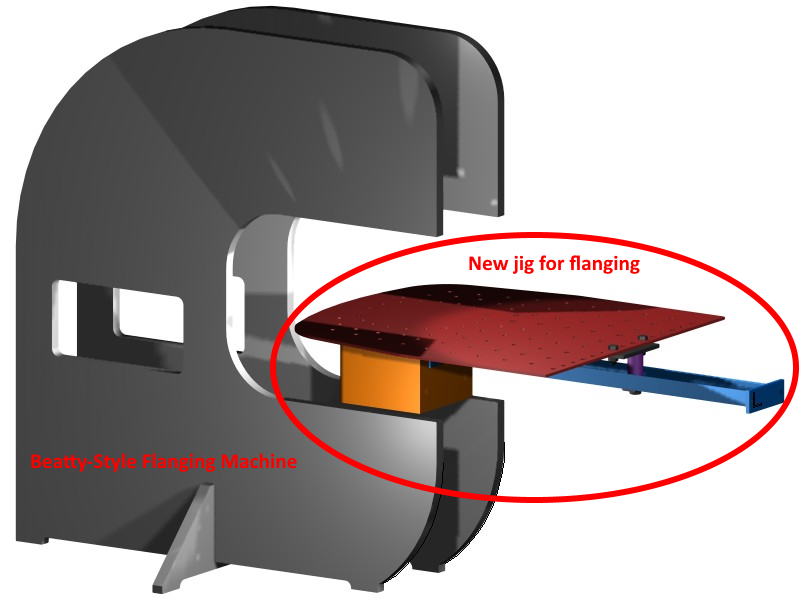

Meanwhile, Gordon Cook is designing a fixture and jigs for the flanging machine. It will be used to form the large radius curved sections of the top of the door sheet and the rear tube sheet. The idea is to hold these large sheets in the proper position to achieve the best results. They are difficult to maneuver in the flanging machine, and the pivot will ensure that they will have the correct radius.

And our own shop crew is now actively seeking machinists who would like to volunteer their talents towards the Build 11 project. In short, we are ready to machine a plethora of castings and parts – and could use some help. If you are a qualified machinist in the Midcoast Maine area, please email us at info@wwfry.org to learn how you can help Build 11.

It is also planned to modify our home-built Beatty-style flanging machine to serve as a brake, adding another layer of versatility to this most useful tool. With that, we will be able to manufacture various parts for coach No. 9’s trucks. While we have a number of parts already on hand made for us by Cattail Foundry, we need a few more components before we can begin to machine and then assemble the trucks. As for Coach No. 9 itself, the exterior is essentially complete, so Eric and Ron and Lou will soon turn their attention to the interior of the car.

It is also planned to modify our home-built Beatty-style flanging machine to serve as a brake, adding another layer of versatility to this most useful tool. With that, we will be able to manufacture various parts for coach No. 9’s trucks. While we have a number of parts already on hand made for us by Cattail Foundry, we need a few more components before we can begin to machine and then assemble the trucks. As for Coach No. 9 itself, the exterior is essentially complete, so Eric and Ron and Lou will soon turn their attention to the interior of the car.

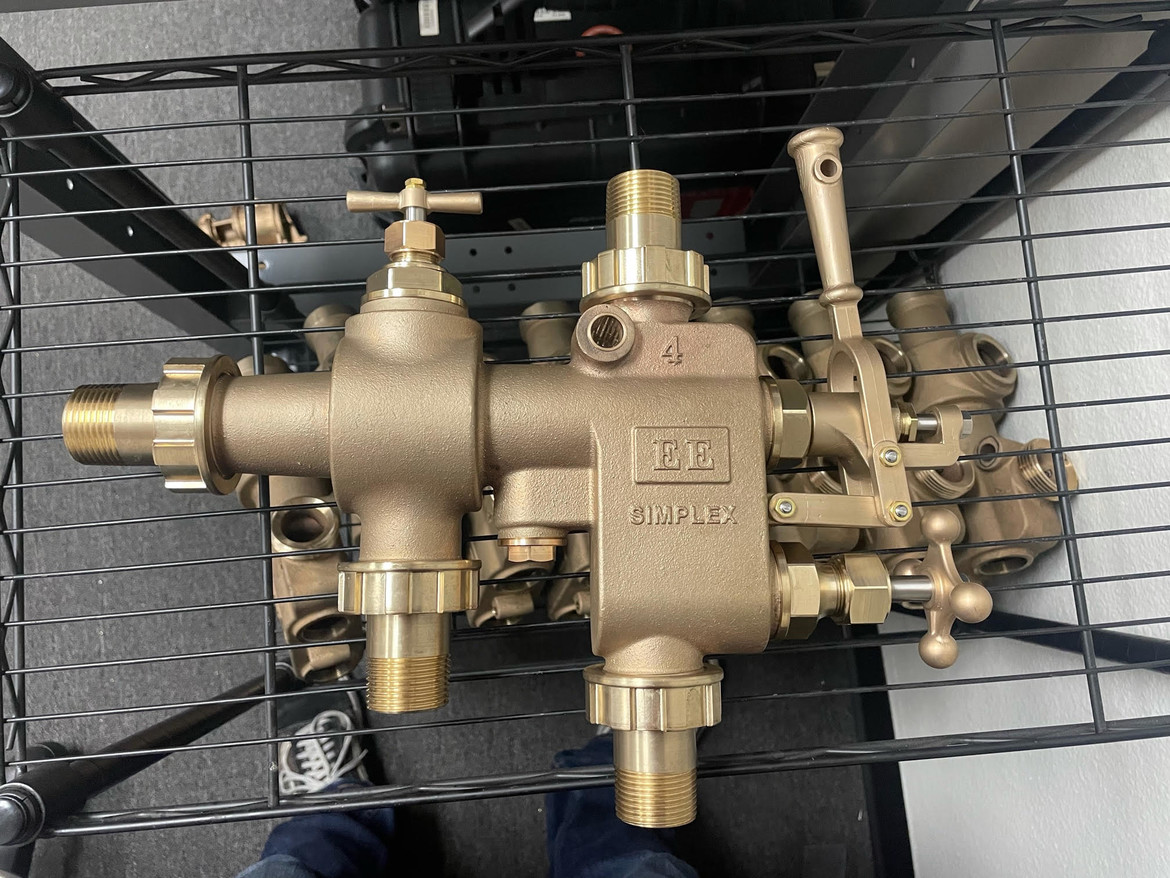

And to the delight of our hard-working steam crews, a brand spanking new Nathan “Simplex” No. 4 boiler injector, made by Eccentric Engineer of Orange, California, has been purchased and is being installed to replace a troublesome “legacy” injector on locomotive No. 9. Some minor modifications of the piping will be necessary, as will making a bracket to hold the device. If this injector proves successful on locomotive No. 9, additional injectors will be ordered for locomotive No. 11.

And to the delight of our hard-working steam crews, a brand spanking new Nathan “Simplex” No. 4 boiler injector, made by Eccentric Engineer of Orange, California, has been purchased and is being installed to replace a troublesome “legacy” injector on locomotive No. 9. Some minor modifications of the piping will be necessary, as will making a bracket to hold the device. If this injector proves successful on locomotive No. 9, additional injectors will be ordered for locomotive No. 11.

Learn more, get involved, and contribute at build11.org

Over several days in June, various members of the No. 11 engineering group worked at Sheepscot. They installed new cranes in bay 1 and bay 3 of the shop. In addition, during another work session they completed all the components for the rear frame extension of No. 11 that required bending. Several of those items were machined and found to be within 0.01 of perfect.

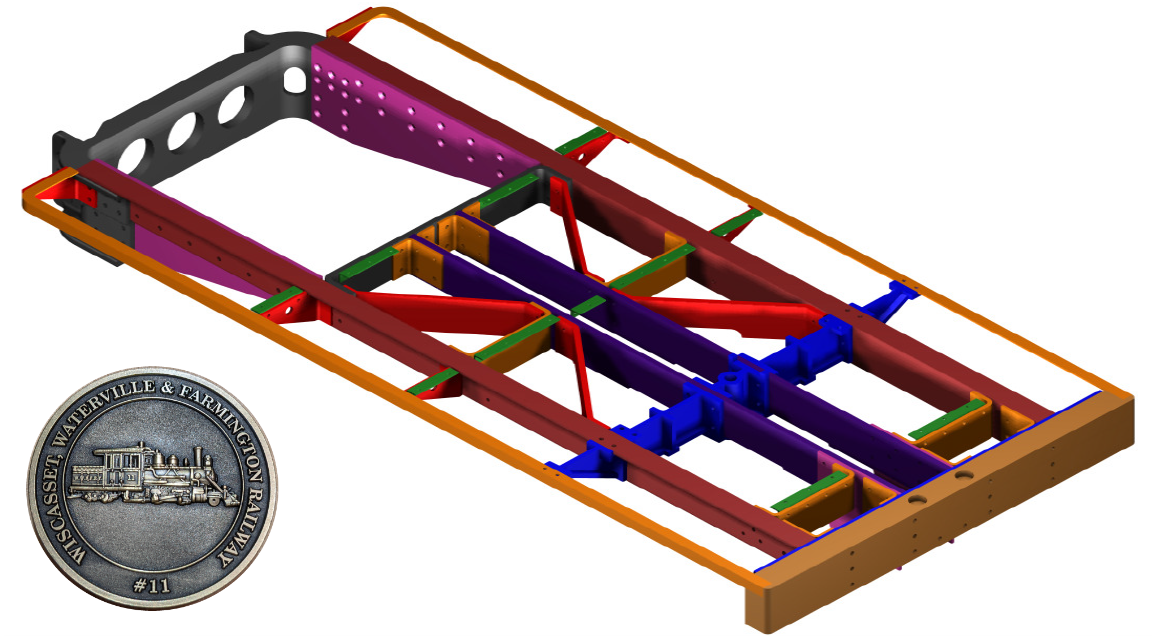

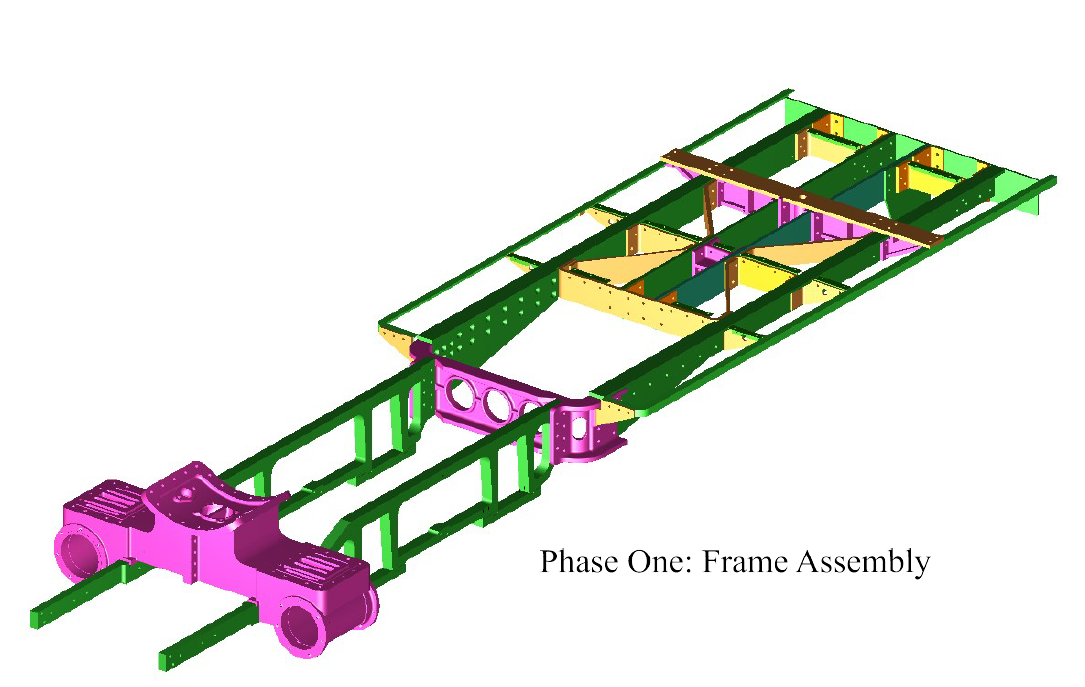

Gordon Cook has produced an image of the Phase 1 work on No. 11, the assembly of the main frames of the locomotive. As work progresses on the actual assembly, we will update this image.

Gordon Cook has produced an image of the Phase 1 work on No. 11, the assembly of the main frames of the locomotive. As work progresses on the actual assembly, we will update this image.

We received the welcome news that pattern work for the locomotive’s cylinder half-saddles is proceeding at Dakota Foundry. They have sent us several photos.

We received the welcome news that pattern work for the locomotive’s cylinder half-saddles is proceeding at Dakota Foundry. They have sent us several photos.

Thanks to a couple of eagle-eyed members, we have been able to acquire an appropriate steam gauge and a genuine Eames Vacuum Brake gauge though on-line auction. Several WW&F members contributed funds to allow the purchase of authentic items needed for No. 11.

Thanks to a couple of eagle-eyed members, we have been able to acquire an appropriate steam gauge and a genuine Eames Vacuum Brake gauge though on-line auction. Several WW&F members contributed funds to allow the purchase of authentic items needed for No. 11.

Our 2021 fund raising for No. 11 is proceeding amazingly well. As of July 11, we have received $39,677.00, including $12,820.00 in matching funds from our anonymous donor. This brings us to 51% of the $50,000 Challenge (which concludes on October 31st) and to 80% of our overall goal for 2021!

Our 2021 fund raising for No. 11 is proceeding amazingly well. As of July 11, we have received $39,677.00, including $12,820.00 in matching funds from our anonymous donor. This brings us to 51% of the $50,000 Challenge (which concludes on October 31st) and to 80% of our overall goal for 2021!

Meanwhile, we’ve sent out more 20 of the full-size builder’s plate replicas, as well as 10 of the 3-D printed version. Our raffle for one of the bronze plates has raised more than $350 – and there are plenty of tickets available. The drawing takes place on Saturday, October 9 during the Fall Work Weekend.

Learn more, and contribute at build11.org